Industrial Ethernet switches

Industrial switches are also known as industrial Ethernet switches. At the beginning of the design, the Ethernet switch does not take into account the functional requirements of the industrial network. Therefore, when the network equipment is deployed in the industrial field, the stability of the commercial switch in the face of the harsh working environment is severely challenged. In this regard, industrial Ethernet switches with high reliability, stability and security have become a transmission tool that can adapt to complex industrial environments and facilitate the deployment of industrial automation networks.

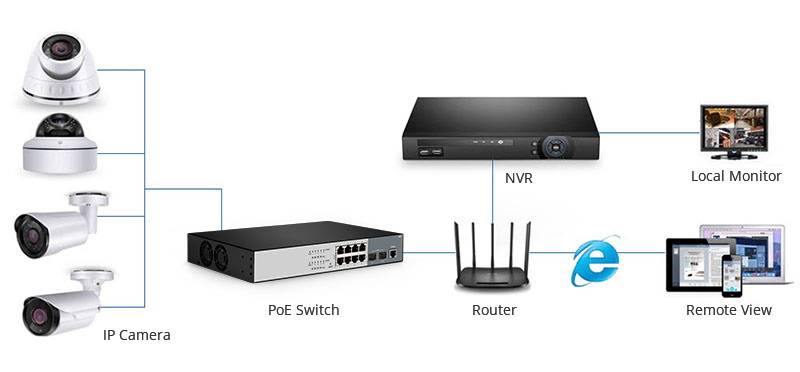

In industrial environments, there is a need for switches to be prepared for specific needs. Industrial switches are especially used for different network connections, such as energy distribution in electrical branches, as well as monitoring and controlling the operation of security cameras.

Industrial Ethernet switches provide the network connection between the industrial environment and the applications of business companies and are made for industrial use. Locations from company floors to traffic control last and stay.

Industrial switches are designed to withstand the toughest working environments, with an extensive product line and flexible port configurations to meet the needs of a wide range of industrial control applications. With the rapid development of power, metallurgy, petrochemical, environmental protection, transportation, construction and other industries, the demand for industrial Ethernet switches is also increasing.

So, what are the advantages of industrial switches compared to commercial PoE switches? As a PoE switch manufacturer, Everiont introduces you in detail.

The main advantages of industrial switches

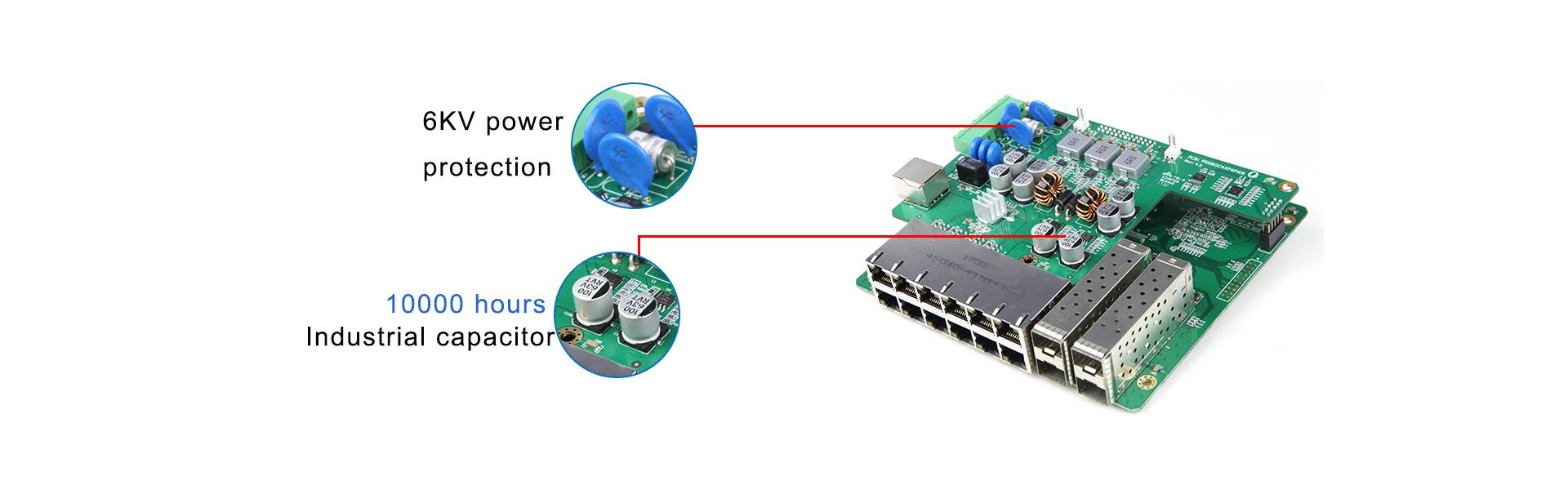

1. Use of industrial grade raw materials

Industrial switches have requirements for the selection of parts and must be able to withstand harsh environments, so they can adapt to industrial environments and support industrial applications in harsh environments.

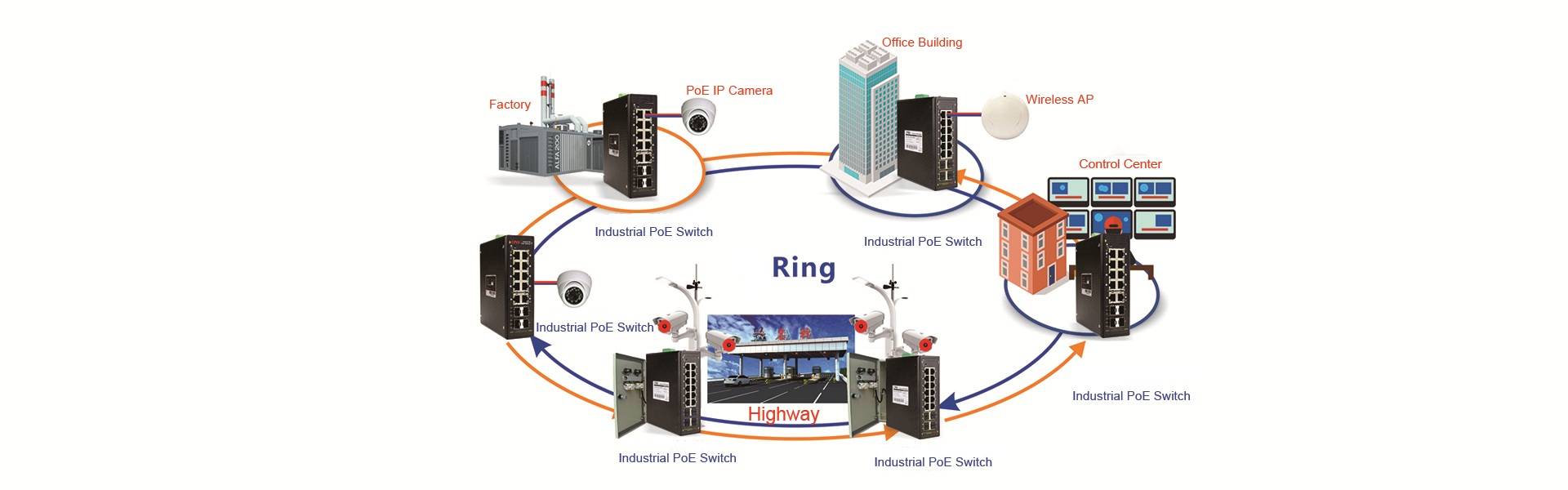

2. Ability to ring, backup link

Industrial switches generally have a fast loop and backup network, and the system overhead can be less than 50 milliseconds. Although commercial PoE switches can also form ring networks, the self-healing time is more than 10-30 seconds, which cannot meet the needs of industrial environments.

3. High anti-interference performance

Industrial switches have strong anti-interference performance, can work in harsh electromagnetic environment, and have a high level of protection in lightning protection, waterproof, anti-corrosion, anti-shock, anti-static, etc., while PoE-grade switches They are commercial and do not have these features.

4. Compatible with high temperature environment

Industrial switches generally use a corrugated metal cover for faster heat dissipation and more protection. They work well in the temperature range of -40°C to +75°C and can adapt well to complex temperature and humidity conditions. Commercial PoE switches can only work in the range of 0 to 50 degrees Celsius, which cannot work in harsh weather conditions.

5, additional power supply design

Power supply is a very important part of industrial switches. Power outages generally account for more than 35% of equipment failures. To avoid the problem of power failure, industrial switches use dual power supply redundancy to ensure stable and reliable operation. Commercial PoE switches generally use a single-source AC power supply, which is not suitable for industrial environments.

6, long life

Industrial switches use industrial-grade solutions from shell materials to accompanying components, so the product has greater reliability and longer life. The useful life is more than 10 years, while the useful life of ordinary commercial PoE switches is 3-5 years.

What points should I pay attention to when buying a network switch?

The main factors in choosing an industrial switch

1, reliability

Reliability is important in industrial environments. Factors related to product reliability are the hardware tolerance of the equipment to the working environment: such as operating temperature range, EMC electromagnetic compatibility, lightning protection level, installation and power supply mode, fanless design, redundancy, fault detection and flexibility, etc. In the description of the product parameters, there should be a detailed description of the working temperature range, electromagnetic protection and lightning protection level.

2, transfer time

Network data transmission causes delay. Therefore, the first point for choosing an industrial Ethernet switch is the delay of the switch port when sending data frames. In a standard factory automation control system, the system can tolerate a response time of no more than 10 milliseconds. Therefore, when choosing a switch, the delay of the switch port should not exceed 10μs.

3, compatibility

Industrial Ethernet switches and other industrial Ethernet components must be able to communicate using the standard TCP/IP protocol. There should be no incompatibility between industrial Ethernet devices and commercial Ethernet devices. For various industrial field bus solutions, industrial Ethernet devices must have appropriate capabilities and compatibility.